As of this evening, I have completed almost all of the final parts that will comprise the monarch butterfly. I am only missing antennae. The wings are now constructed with 3D printed veins and a white canvas like textile, very light weight. Also, the electronics work well and the construction of a control box to house the Pololu board, switches, and connectors was enjoyable.

After completing this build for the first time, I needed to make several adjustments to the steel axle rods and connecting bolts. I also discovered the abdomen is too long so I will sew another one. The discovery of true proportions and how pieces fit next to each other is surprising and magical. The parts alone don’t seem very significant, but when they nestle well with each other in an overall assembly, like the thorax, it makes me think of a creating a kit product.

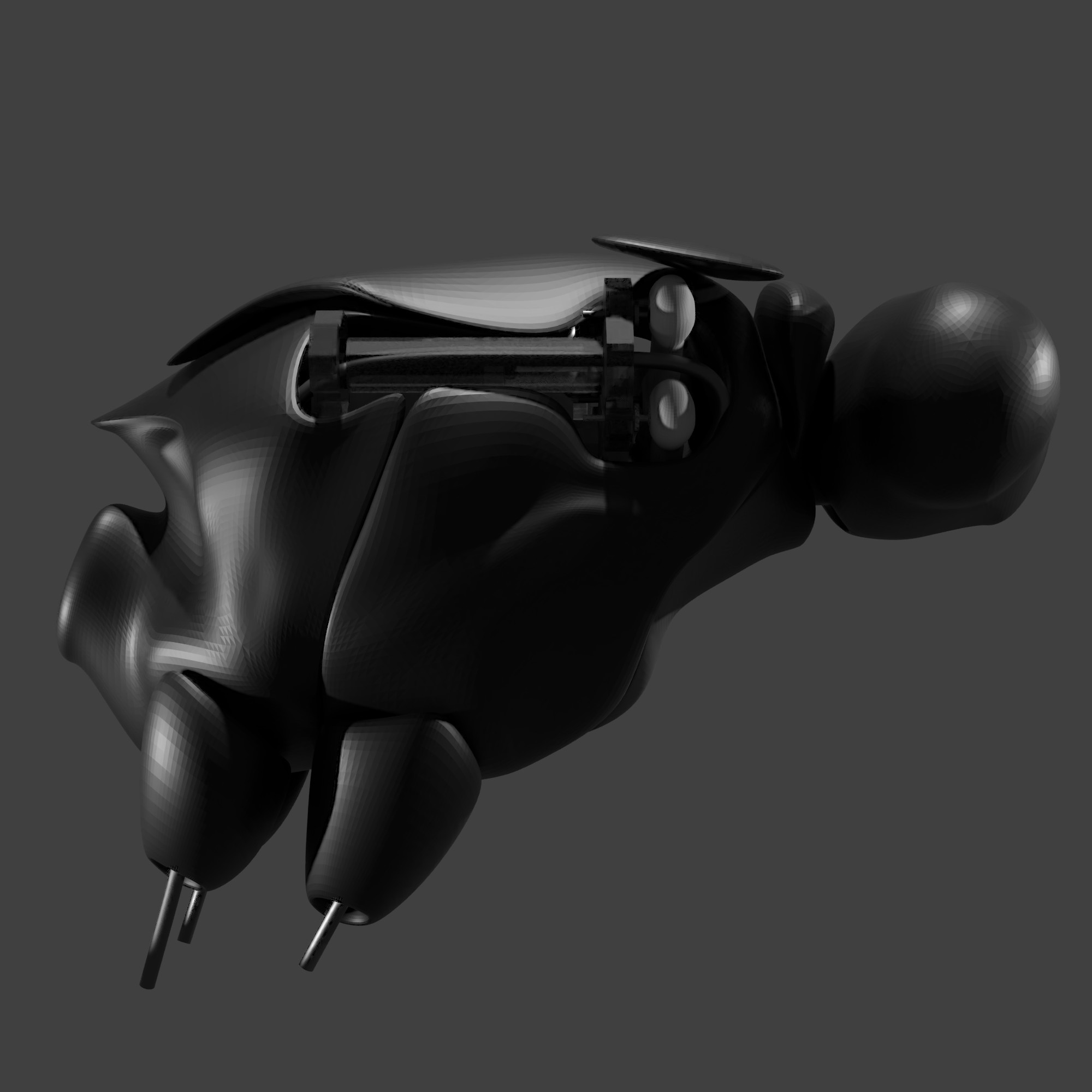

The final monarch pieces before first assembly.

Here is a list of the parts in the image:

Wing pair front and rear

Wing axles, linkages, and ball screws

Scutum

Scutelum

Prosternum

Mesosternum

Metasternum

Head

Abdomen

Servos

Six legs, two tiny front legs, and four larger rear legs

The body still needs the white dots which cover the real monarch butterfly. I’ll do that as an ultimate final touch, as well as a little hair trimming here and there. The monarch has longer hair like structures on its scutelum, abdomen, and front pair of wings.

I am creating a video of the project as well, so in a month or so I will release that online.